Manufacturing Capacity

Professional Research and Development Team

TGQ has a professional R&D team and production team. In addition to continuously improving our expertise and technology, TGQ also focuses on improving equipment. TGQ has formulated the manufacturing standards for the top automotive chassis suspension system and has accumulated more than 30 years of practical experience.

Safest, High Quality and High Performance Products

TGQ become a benchmark manufacturer of reliable suspension system parts for world-renowned automobile brands. We focus on providing the safest, highest quality, and most efficient products. To pursue and realize the concept, TGQ continuously trains and learns the professional skills of the research and development and product teams.

We invest in automated hardware equipment yearly for more manufacturing technology than our peers. TGQ adheres to a critical point: “Even if it is the best, still pursuing A to A+.” TGQ has been established for more than 30 years, has invested in production equipment, and regularly maintains, inspects, and updates.

The planning of production lines can meet customer needs to achieve instant, fast, and efficient configuration and changes.

Stamping

Features

- Expert in complex Curved Surface

- High Strength, Smooth and Supple, no Scars, no Burrs

Production Capacity

- Minimum lot size: 100 ~ 1,000 pcs

- Maximum monthly Capacity:30,000 ~ 100,000 pcs

| Materials Used with Specialization | ||||||

|---|---|---|---|---|---|---|

| Material No. | JIS/SAE No. | Classification of Materials | Material Name | Hardness | Tenacity | Rate of Elongation |

| SPHC | JIS G 3131 | Board | Hot Rolled Sheet | HRB 55-70 | Higher Than 270N/mm2 | More Than 29% |

| SAPH440 | JIS G 3113 | Board | Hot Rolled High Tensile Steel(Black Plate) | HRB 75-90 | Higher Than 440N/mm2 | More Than 32% |

| S50C | JIS G 4051 | Board | Medium Carbon Steels for Machine Structural Use | HB 179-235 | Higher Than 608N/mm2 | More Than 18% |

- Manufactured thickness::0.8mm-8.0mm

- Maximum finished size::400mm-600mm

| Major Equipment | ||

|---|---|---|

| Name of Equipment | Specification | Quantity |

| Stamping Machine | 250 Tons | 3 Pcs |

| Punch press | 200 Tons | 1 Pcs |

| Punch press | 110 Tons | 1 Pcs |

| Punch press | 45 Tons | 5 Pcs |

| Punch press | 15 Tons | 10 Pcs |

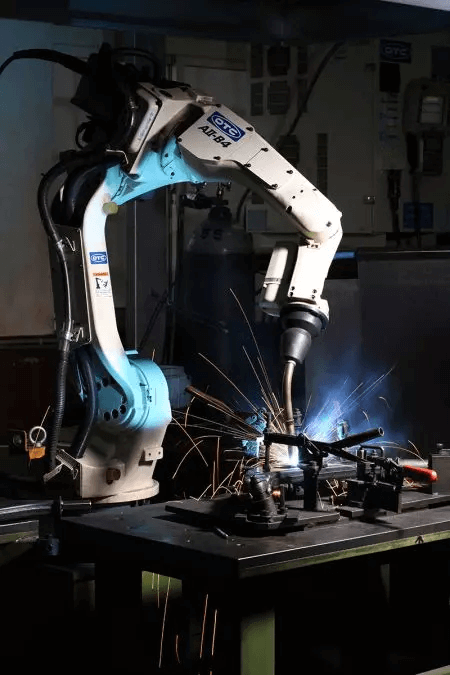

Welding

Perfect bonding, stubbornly beyond the strength of steel plates.

Flattened Weld with delicate surface, no welding slag.

Major Equipment

OTC (Japan) automated CO2 welding robots : 4 pcs

Production Capacity

- Minimum lot size:100 ~ 1,000 pcs

- Maximum monthly capacity:10,000 ~ 100,000pcs

Machining

Technology of Multi-material Turn-milling Process : Barrel Rod, Aluminum Extrusion, Casting and Forging.

Challenging the Goal of 6 Sigma and 0 PPM (Zero Defect).

Features

- Mirror Polished Ball Joint: Surface Roughness:<Ra 0.2.

- Circularity:+/- 0.01mm.

- Tolerances for inner and outer diameters: ±0.005mm

- Precision Development:Circularity: 0.01 mm & Concentricity: 0.1mm.

Production Capacity

- Minimum lot size: 100 ~ 1,000 pcs

- Maximum monthly capacity: 10,000 ~ 100,000 pcs

- Annual capacity (semi-finished control arms): 600,000 pcs

- Annual capacity (ball studs): 1,000,000 pcs

| Materials Used with Specialization | ||||||

|---|---|---|---|---|---|---|

| Material No. | JIS/SAE No. | Classification of Materials | Material Name | Hardness | Tenacity | Rate of Elongation |

| S45C | JIS G 4051 | Bar | Carbon Steels Of Machine Structural Use | HB 167-229 | Higher Than 569N/mm2 | More Than 20% |

| SCM440 | JIS G 4053 | Bar | Chrome-Molybdenum Steel | HRC 30-378 | Higher Than 981N/mm2 | More Than 12% |

| A6082 | JIS H 4140 | Bar | Aluminum-Magnesium-Silicon Alloy | HRB 57-63 | Higher Than 310N/mm2 | More Than 10% |

| FCD400 | JIS G 5502 | Forged | Spheroidal Graphite Cats Iron | HRB 75-89 | Higher Than 400N/mm2 | More Than 15% |

| Major Equipment | ||

|---|---|---|

| Name of Equipment | Specification | Quantity |

| Mini CNC Lathe | Radius of Gyration of 400mm | 6 sets |

| Large CNC Lathe | Radius of Gyration of 600mm | 10 sets |

| Automatic Lathe | Robot Arm Production Line | 4 pcs |

| MC Milling-Vertical Machining Centers | 1200mm Platform | 8 sets |

| Ball Joint Polishing Machine | Spherometer Φ20-40mm | 4 sets |

Rubber Technology

Rubber Bushings

Hydraulic system design, multiple appropriate flexibility, precise quakeproof demand

Dust-Proof Cover

More than one million times of ultra-durable life test under extreme weather environment of highest temperature of 160°F and lowest temperature of -40°F.

Production Capacity

- Minimum lot size: 100 ~ 1,000 pcs

- Maximum Monthly capacity: 100,000 ~ 300,000 pcs

| Materials Used with Specialization | ||||||

|---|---|---|---|---|---|---|

| Materials No. | JIS/SAE No. | Classification of Materials | Material Name | Hardness | Tenacity | Rate of Elongation |

| NBR | JIS K 6253 | Rubber | Nitrile Butadiene Rubber | 50-85 | 50-250Kg/cm2 | 800-100% |

| NSR | JIS K 6253 | Rubber | Natural Rubber + Styrene Rubber | 50-85 | 30-300Kg/cm2 | 1000-100% |

| CR | JIS K 6253 | Rubber | Chloroprene Rubber | 50-65 | 50-250Kg/cm2 | 1000-100% |

| Major Equipment | ||

|---|---|---|

| Name of Equipment | Specification | Quantity |

| Rubber Injection Molding Machine | 200 Tons | 6 sets |

| Vacuum Injection Molding Machine for Rubber | 250 Tons | 2 sets |

| Shrinker | 25-100mm | 2 pcs |

| Anti-corrosion Coating Production Line | 3 Lines | |

Assembling Technology

Adhering to serious demand on all details, achieving superb technology.

Major Equipment

6 composite assembly lines for chassis suspension and steering system parts

Features

- 60,000 km strong warranty/ 3 years for more than 1 million times of high and low temperature mud water life tests.

- Solid Body of Control arm

- Torque Gap of Ball Joint Works Precisely

- Excellent Elastic Quakeproof of Rubber Bushing