Our service

One-stop Processing Serives

TGQ materials processing services revolve around the technology of control arm manufacturing, which is widely utilized across various industries. We provide comprehensive services that can accomplish vertical integration in your needs.

In TGQ, you can get a one-stop service experience. We can fulfill your needs, whether it’s CNC machining, complicated curve stamping, surface finishing, or branding services (such as branded packaging and laser engraving).

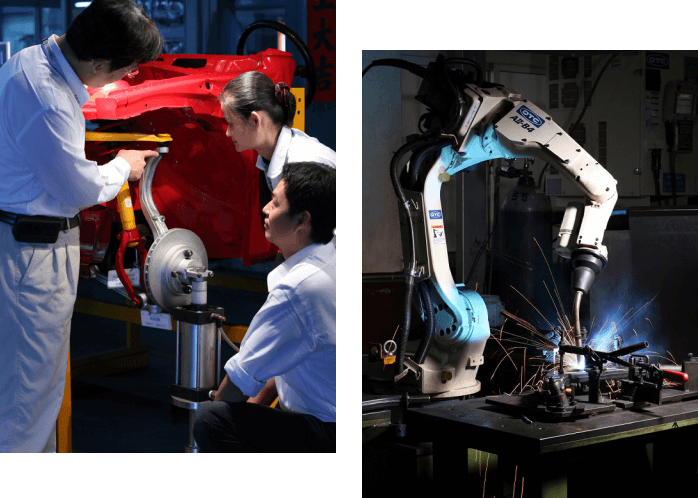

Manufacturing control arms requires multiple processing stages, giving us plenty of experience in processing. Additionally, control arms are considered safety components in automotive parts, demanding no tolerance for quality failure. This strict requirement has honed our meticulous standards for quality.

Accumulating experience in control arm production and stringent quality control has earned us recognition from domestic and international customers. We provide processing services with the same professionalism and enthusiasm.

OEM/ODM

TGQ specializes in various parts manufacturing processes, including CNC machining, shearing, forging, stamping, electric welding, rubber injection, assembly packaging, etc. We can assist customers in balancing quality, time, and cost – according to their specific requirements.

Upon receiving initial drawings, ideas, or samples, we hold development meetings with customers to visualize the product. We design dies and fixtures and establish specifications while discussing relevant data and adjusting the product as needed. All processes adhere to the project workflow based on our company. Our primary focus is vertical supply chain integration and a wide variety of processing services. This eliminates the need for customers to engage multiple vendors, reduces the risk of errors, and minimizes associated costs.

Since our R&D department is located at the factory, we can effectively identify and resolve issues during the project. We use control points to reduce manufacturing instability. We strive to preserve our customers’ design to the fullest extent while leveraging our team’s years of experience to enhance product performance. In case of any product-related issues, we prioritize two-way communication to create a reliable customer experience.

Applications

Our services can be applied to various industries depending on the equipment used, including:

Medical, Mechanical Components, Hardware Products, Home Decor Accessories, Electronic Components, Figures & Models, Electric Scooters, Bathrooms, Cosmetics, Gardening supplies, Aircraft, Outdoor Equipment, Hand Tools, Rubber Applications, Bicycles, Handcarts, Railways, Utensils, Household Appliances.

Capability

| Equipment | Specifications (tons) | Quantity |

| Hydraulic Forming Machine | 250 | 3 |

| Punch Press | 200 | 1 |

| Punch Press | 110 | 1 |

| Punch Press | 45 | 5 |

| Punch Press | 15 | 10 |

Equipment | Specifications | Quantity |

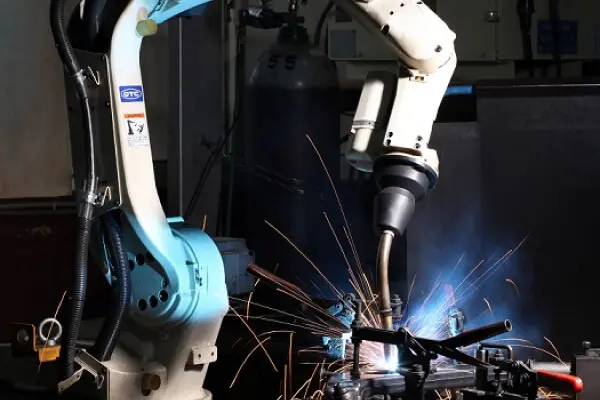

Japan OTC | Full- automatic CO2 Welding Robotic Arm | 4 |

Equipment | Specifications | Quantity |

Small CNC Lathe | Radius of gyration of 400mm | 18 sets |

Large CNC Lathe | Radius of gyration of 600mm | 6 sets |

Automatic Lathe | Robot Arm production line | 4 lines |

MC Milling – Vertical Machining Centers | 1200mm Platform | 8 sets |

Ball Joint Polishing Machining | sphere diameterΦ20~40mm | 4 sets |

Equipment | Specifications | Quantity |

Rubber Injection Molding Machine | 200 tons | 6 sets |

Vacuum Injection Molding Machine for Rubber | 250 tons | 2 sets |

Shrinker | 25~100mm | 2 sets |

Anti-corrosion Coating | Production line | 3 lines |

Aluminum Forging Process

| JIS No. | Chemical Composition | Hardness (HB) | tensile strength (N/mm2) | yield strength (N/mm2) | Elongation |

| 6061-T6 | Al,Mg,Si | 95 | 310 | 275 | 12% |

| 6082-T6 | Al,Mg,Si | 95 | 310 | 280 | 10% |

Process

Service Process

Providing Information

Images, Samples

Communication of Requirements

3D Scanning

100% Surface Comparison of Samples

Design Specifications

Functional Performance, Mechanical Strength, Hardness, Toughness, Material

Product 2D/3D Design

Final Product Drawings, Part Drawings, Mold and Inspection Tool Drawings

Mold, Jig and Inspection tools Fabrication

Prototyping

310 pieces to Verify Product Performance Meets Requirements

Trial Production

50-100 pieces, Establishing Special Quality Control Points

PPAP

Production Part Approval Process) Documentation Preparation (ERP Data Setup

Mass Production

Contact Us for Quality Service.